Intro

Nowadays, the fast-pacing global market of goods requires businesses of all industries to be prompt and flexible in their production, delivery, and other operations. The best solution that modern IT companies can suggest is the digitalization of processes. In industrial matters, of course, it means utilizing the Internet of Things. One of the most significant tasks is to organize efficient supply chain management and logistics to enable production stability. All requirements and demands can be fully satisfied by the practice of the IoT for supply chain.

In this article, we’ll present you with our analysis of the importance of employing the IoT for logistics and management of the supply chain, describe the impact of the Internet of Things solutions on the overall business and customer relationship management, and give some examples of the most common use cases. Doing the research on the matter of supply chain IoT we use global statistics and our own experience as Atlasiko Inc. is an experienced provider of the Internet of Things services.

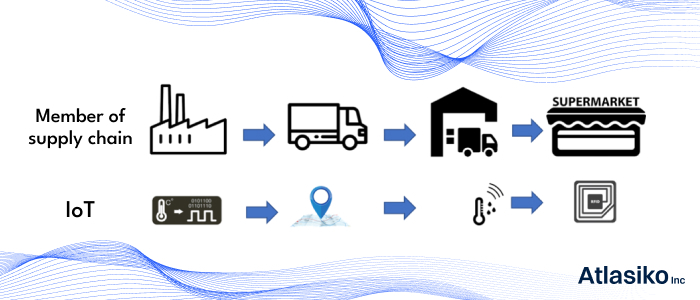

Work of IoT in supply chain management

We’ve already described the general meaning and the main concepts of IoT, so check out our previous Internet of Things article to call it to mind.

Now, let’s focus on the work of supply chain IoT and how it impacts logistics and production. The Internet of Things consists of different gadgets and devices connected to the Internet e.g. GPS trackers, sensors that gauge humidity, the temperature of the environment or the production, translate images, etc. With the help of IoT in logistics and its use in supply chain management, you can gather real-time information about the conditions of stored or transported products, monitor their status in the process of shipment or the amount in storage, etc. The sensors in the supply chain Internet of Things also allow processing of the received data and enable quick reaction to any atypical changes that can damage the goods or interrupt the production or logistics procedures. Such continuous monitoring and analysis performed by IoT in supply chain management ensure sustained end-to-end manufacturing and delivery without delays.

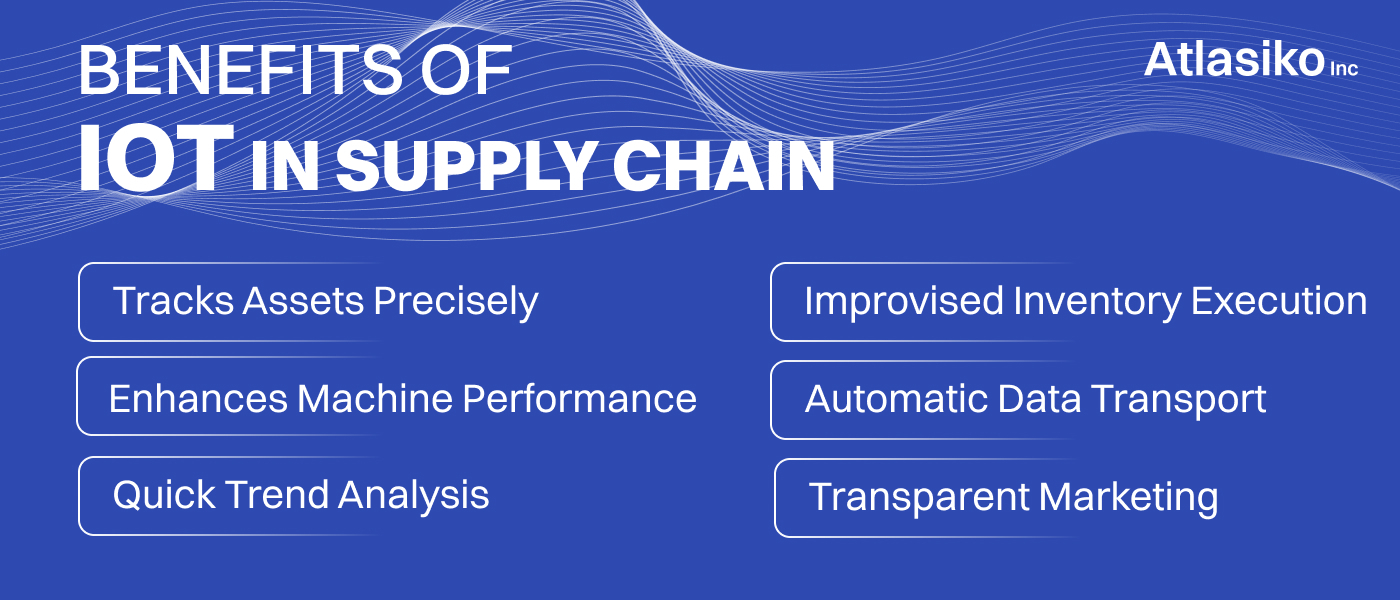

Benefits of IoT for supply chain and logistics

The Internet of Things in supply chain management as well as sensor-based logistics have proven their efficiency and beneficial impact on business progress. Read ahead to find out all the advantageous capabilities and opportunities of advancements that supply chain and logistics IoT can bring to your organization.

Real-time tracking

One of the most useful features of the Internet of Things solutions is that they have special sensors enabling the gathering, transferring, and analysis of information in real time. Such beneficial characteristics make the supply chain and transportation of goods easy to control and organize as you get the data directly and immediately. The technologies of the IoT in supply chain management allow specialists to instantly check the goods in inventory, and their condition, respond to any changes in the status of orders without delays, etc.

Automation

In modern industries, automation takes a significant place for all businesses in order to reduce the amount of manual work and labor costs, decrease the possibility of human factor mistakes, increase the velocity of resource delivery, and many other reasons. For manufacturers, the supply chain IoT enables the required automation of this segment of management and industrial procedures. You can use drones as means of IoT in warehouse management or create a whole infrastructure with a remote control to monitor logistics progress.

Transparency

With the automation of functioning in the Internet of Things supply chain and immediate data gathering, you can ensure the maximum level of transparency of practically all operations. All information about the activities with raw resources, assets, or finished products is constantly tracked. You can check on the inventory and storage with the IoT in warehouse management at any time, audit all incoming and shipped-off products, review automated reports, monitor the transportation progress via IoT GPS solutions, etc. This way, IoT in logistics and supply chain control provides the maximum assurance of preventing procedure deviation, unnecessary spending, or unauthorized activities with materials.

Hastened processes

The velocity of the supply delivery and operations highly influences the overall production and major tempos of your business growth. Undoubtedly, the IoT for supply chain organizations arranges the streamlining of SCM and speeding up the following activities. With the consolidation and centralization of IoT supply chain management, you also accelerate the work of other sectors and departments in your company.

Efficient resource management

Innovative Internet of Things solutions help to organize and control resource provision and distribution in the most productive ways. Automated analytics and reports made by IoT in the warehouse management system will provide you with the data on what materials your factory is running low on stock, what resources are being shipped to you at the moment and their status, or even analyze statistics and show the pricing changes on the market. IoT for supply chain can quickly detect any leaks in resource allocation and find inefficient points or possible failures of the equipment.

Asset tracking

Use the capabilities of the IoT for supply chain to facilitate asset management. With the help of IoT devices e.g. smart materials, sensors, RFID tags, etc., you can track the condition and location of each asset item. Such technologies allow managers to quickly receive all important info on the delivered product or material.

Predictable logistics

The Internet of Things technology developers, like Atlasiko Inc., provide companies of different industries with efficient GPS trackers and responsive software for monitoring shipment progress. With IoT logistic solutions, managers can easily forecast the delivery time with the ensured mitigation of consequences in the case of delays. Moreover, modern logistics IoT can analyze the available data and predict weather conditions, possible traffic jams, suggest the best routes, and send immediate risk alerts to preclude postponements.

Improved CRM

The supply chain Internet of Things solutions and logistics software are useful not just for managers but for customers too. Many companies present their client base with special customer-facing apps so they can see the status of their order and basically track the transportation via GPS at the same time as the product provider. When customers can monitor the delivery headway of their goods all the way to their doors, it assists in establishing trustworthy relationships and organizing the accounts of finished orders.

Challenges of the utilization of supply chain IoT

- Sustainable connection

Apparently, one of the biggest threats to the functioning of the Internet of Things in logistics and supply chain management is Internet access disruption. To successfully utilize all functions of supply chain IoT, you need to organize a stable network connection with sufficient speed to be able to collect and transfer data continuously. - Employee training

Even though most processes of the supply chain get automated with IoT devices and software, you still need workers to operate these gadgets in warehouses and vehicles. To solve this challenge, managers or IoT service providers have to grant adequate training to the employees. Atlasiko Inc - Security

The security issue is an overall concern that appears in most cases of implementation of new information technologies in business. Choosing a supply chain IoT services provider, make sure they pay close attention to detecting any data processing and storage vulnerabilities and ensuring solid protection from outside threads and leaks. Performing IoT services, Atlasiko Inc. always provides the best cybersecurity solutions for the safety of your data. - Data storage issues

With the proper work of IoT in supply chain and logistics, the amount of data collected by sensors will increase in geometric progression every working hour. Therefore, you’ll need adequate server power to be able to contain and process the received information. In this case, enterprises tend to request our Big Data solutions in addition to the IoT for supply chain.

Even though some development projects might appear challenging, professionals of our team take it upon themselves to create an unparalleled solution. We develop programs keeping in mind business needs and goals of our clients.Talk to Expert

IoT logistics use cases and digital supply chain examples

Supply chain IoT in the Agriculture industry

Agriculture is one of the most complicated industries to organize a continuous and efficient supply chain. It heavily depends on the velocity of logistics and environmental conditions control as most of the supplies are perishable. Companies also have to take into account the distance of transportation as many of them ship products all around the world. That’s why Internet of Things supply chain applications and devices come in handy for agriculture businesses to ensure proper evaluation, packaging, and shipping of raw production without risks of damaging the quality. Here are some most common ways of using IoT for supply chain by agriculture production providers and distribution firms.

- IoT gadgets can gather operational information that agricultural facilities can utilize to automate inventory management and issue low-supply alarms.

- IoT supply chain solutions can transmit alerts when container conditions don't meet defined specifications in perishable food transportation vehicles, which need specific temperature controls and must comply with FSMA (Food Safety Modernization Act) regulations.

- Remote monitoring of intelligent agricultural equipment enables scheduling and planning of more effective and economical equipment maintenance and repair.

Use of the supply chain Internet of Things in the inventory management

Utilizing IoT for supply chain devices, inventory management is one of the crucial means for arranging and improving each step of the supply chain. Such systems make sure that supplies of raw materials, finished goods, and deliveries reach distributors and customers. It is impossible to exaggerate the significance of asset management in supply chain management. Distributors and transportation firms wouldn't be able to guarantee the efficiency of their intricate supply chain networks without trustworthy data on their inventories.

We researched some major use cases of IoT supply chain software and devices in inventory management.

- Intelligent distribution facilities and warehouses can minimize inventory management mistakes and maintain precise counts of raw materials and finished goods.

- Utilization of IoT in warehouse management enables real-time inventory data updates, tracking availability, and restricting unfulfillable orders.

- Businesses can use machine learning models to improve procedures and avert shortages by identifying repeating patterns in IoT device data.

Logistics IoT and transportation

Transport links all the components of the supply chain together, whether it be via trucks, cargo planes, ocean shipping containers, train trains, or other vehicles. As much as IoT for supply chain may enhance warehouse inventory control, this technology can advance transparency and amend trucking, logistics, and transportation operations.

Frequent cases of utilizing IoT in logistics may be following.

- Products frequently travel to their destination by several different means of transportation. Logistics IoT systems can alter shipment routes using real-time data from GPS to maximize resource efficiency and speed up delivery.

- Predictive analytics can be applied to routes by smart transportation systems using IoT logistic data, indicating supply chain bottlenecks and problems that can be avoided or identified for correction

- IoT supply chain management solutions can help suppliers, vendors, and customers communicate and share information more effectively, allowing transportation businesses to anticipate changes in supply or cargo orders.

- Liable to spoil goods must maintain safe temperatures while traveling from manufacturing to warehousing and distribution, and temperature monitoring during transportation makes sure of this.

Conclusion

There are many different opportunities and advantages that applications of IoT in supply chain management can grant to various businesses. The supply chain Internet of Things solutions improve communication between involved parties, make it easier to track and monitor commodities, and ensure more precise planning.

As long as you have a clear goal for what you need the technology to achieve for you, an IoT logistics and supply chain basis is a great investment for both small and large businesses of enterprise type. It's also essential to bring on a talented team for the design and development phase. Contact Atlasiko Inc., a creative team of software developers, to ensure that your IoT supply chain solution complies with contemporary tech trends and is completely functioning.